| Availability: | |

|---|---|

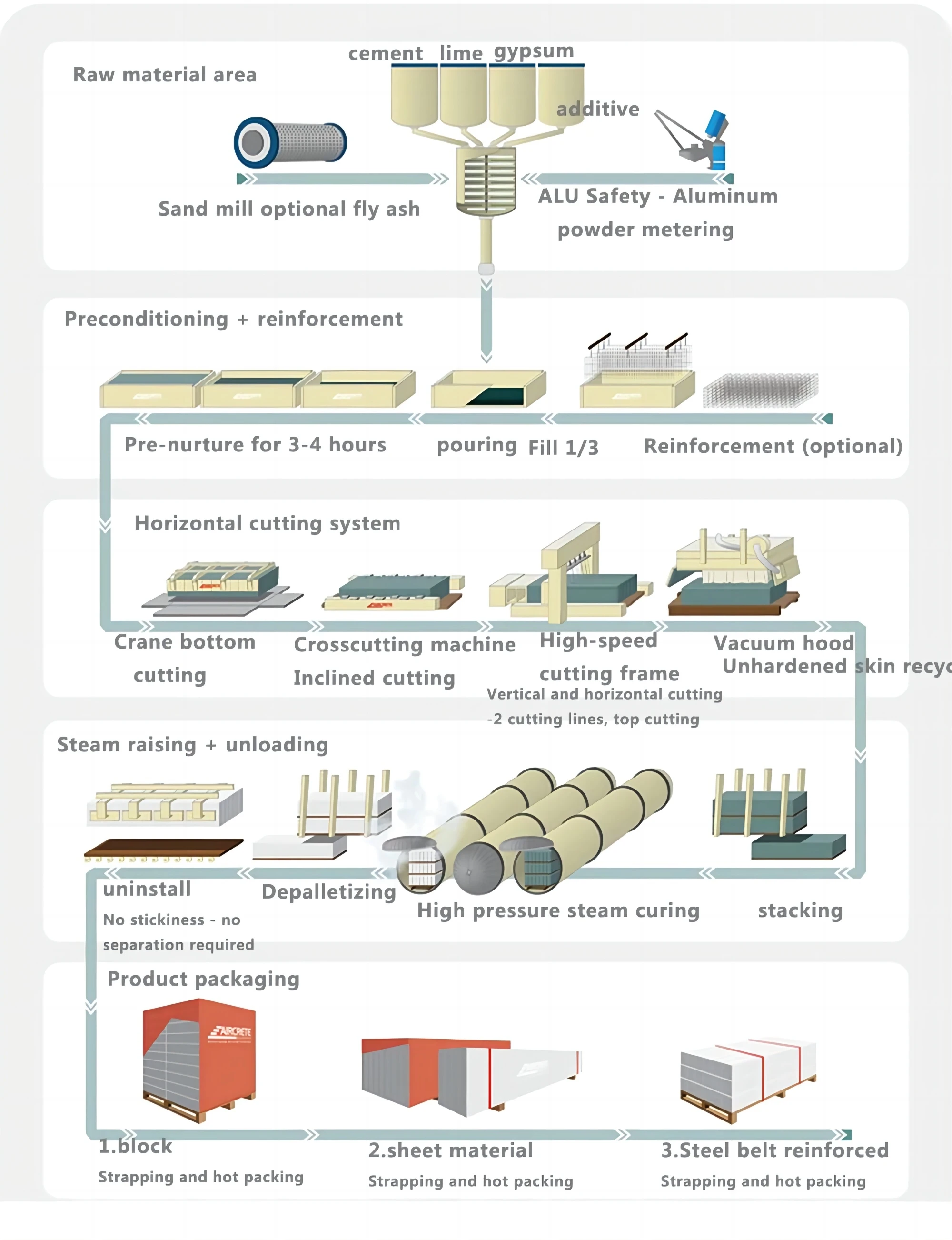

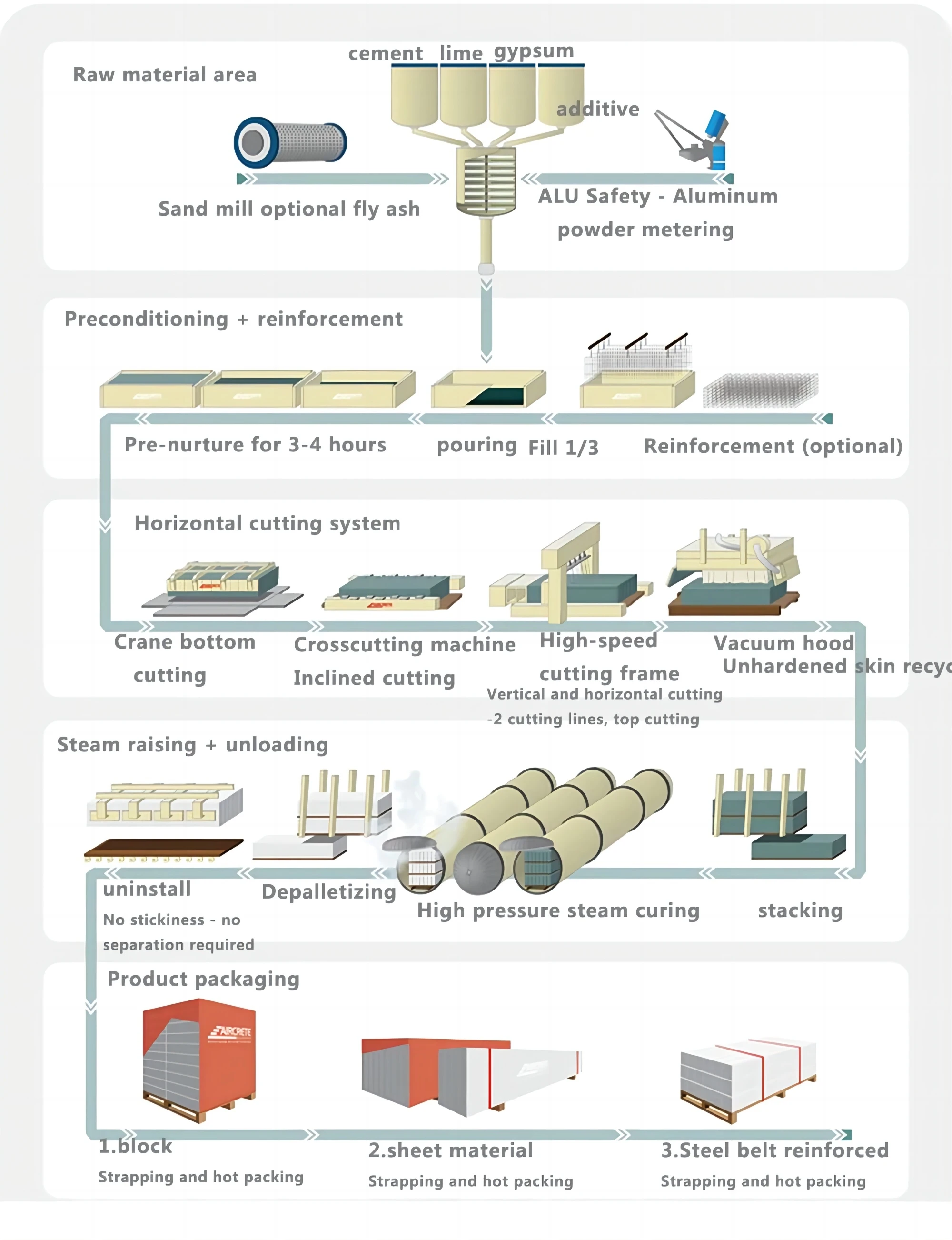

AAC LINE

HUILONG

| ITEM | AAC-5 | AAC-10 | AAC-15 | AAC-20 | AAC-30 |

| Capacity m3/year | 50000 | 100000 | 150000 | 200000 | 300000 |

| Cake Size m3 | 4.2x1.2x0.6 | 4.2x1.2x0.6 | 4.2x1.2x0.6 | 4.8x1.2x0.6 | 4.8x1.2x0.6 |

| Installation Power, kw | 300 | 600 | 600 | 900 | 1200 |

| Production Cycle, mould/min | 5 | 6 | 6 | 6 | 6 |

| Workshop Area,m2 | 3000 | 3000 | 3500 | 4000 | 5000 |

| Plant Area,m3 | 20000 | 20000 | 25000 | 30000 | 35000 |

| ITEM | AAC-5 | AAC-10 | AAC-15 | AAC-20 | AAC-30 |

| Capacity m3/year | 50000 | 100000 | 150000 | 200000 | 300000 |

| Cake Size m3 | 4.2x1.2x0.6 | 4.2x1.2x0.6 | 4.2x1.2x0.6 | 4.8x1.2x0.6 | 4.8x1.2x0.6 |

| Installation Power, kw | 300 | 600 | 600 | 900 | 1200 |

| Production Cycle, mould/min | 5 | 6 | 6 | 6 | 6 |

| Workshop Area,m2 | 3000 | 3000 | 3500 | 4000 | 5000 |

| Plant Area,m3 | 20000 | 20000 | 25000 | 30000 | 35000 |